Login

Join Free

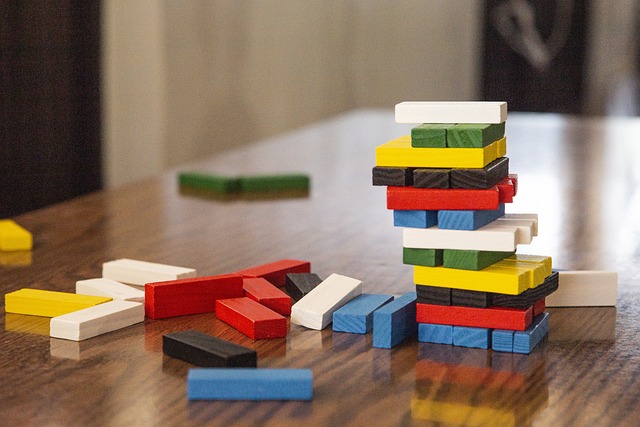

Guide for Buyers When Sourcing Building Blocks: What to Look For Beyond Price

In the highly competitive world of building block toys, it can be tempting to choose the cheapest supplier, especially when products appear similar at first glance. However, experienced buyers know that sourcing quality building blocks involves more than comparing price tags. Factors like material quality, manufacturing standards, safety certifications, and overall durability can greatly affect both customer satisfaction and brand reputation. Here’s a comprehensive guide on what to consider when sourcing building blocks for your business.

1. Why Quality Matters in Building Blocks

Building blocks are not just toys; they are tools for creativity and learning that children use for extended periods. High-quality blocks promote positive customer experiences, contribute to developmental benefits, and meet strict safety standards. Poor-quality blocks, on the other hand, can break easily, lack uniformity, or even pose safety risks due to toxic materials or sharp edges. For these reasons, quality considerations should be a primary focus for buyers.

2. Understanding Material Differences: ABS vs. Non-ABS Plastics

Not all building blocks are created equal, and the choice of material plays a significant role in determining quality:

- ABS Plastic: High-quality building blocks are often made from ABS (Acrylonitrile Butadiene Styrene) plastic, which provides durability, a consistent shape, and a smooth finish. ABS plastic is safe, non-toxic, and heat-resistant, making it an ideal material for children's toys.

- Other Plastics: Lower-quality blocks may use alternative, less durable plastics. These materials might look similar initially, but they can degrade quickly, lose their shape, or emit harmful substances over time. Be sure to ask suppliers about the exact materials used, and don't rely on visual inspection alone.

3. Manufacturing Standards and Certifications

Certifications are essential for building blocks to ensure they meet international safety and quality standards. Reputable manufacturers adhere to rigorous production and quality control practices, which are often validated by industry certifications. Here’s what to look for:

- EN71 Certification: A European safety standard that covers mechanical, physical, and chemical safety of toys.

- ASTM F963: A U.S. standard for toy safety, covering aspects like flammability, toxic elements, and small parts.

- ISO 9001: While not toy-specific, ISO 9001 certification signifies a commitment to quality management.

Request documentation from your supplier to verify compliance with these certifications. Buying from certified manufacturers can provide confidence in the safety and reliability of the building blocks you offer.

4. Safety Considerations: Go Beyond the Basics

Safety is a top concern for building block buyers, as children's toys must meet strict standards to prevent health hazards. Consider the following points:

- Choking Hazards: Building blocks must be designed to minimize the risk of choking. Ensure that the blocks meet size requirements, especially if they're intended for younger age groups.

- Material Safety: Make sure that blocks are free from toxic chemicals, including lead, phthalates, and BPA. High-quality materials are always worth the investment for peace of mind and product safety.

- Surface and Edges: Well-made blocks should have smooth surfaces and rounded edges. Sharp or poorly finished edges can cause injuries and should be avoided at all costs.

5. Durability and Fit: Essential for a Positive User Experience

A common complaint with low-cost building blocks is that they don’t fit together properly, which can be frustrating for children and parents alike. High-quality building blocks offer precision in fit, ensuring stability in assembled structures. Key factors to look for:

- Snug Fit: Blocks should snap together easily and hold firmly without excessive force. Precision is especially crucial for larger sets.

- Uniform Shape and Size: Consistency across all pieces allows for a seamless building experience. Poorly made blocks may have slight size variations that hinder construction.

6. Design Variety and Compatibility with Other Brands

Many buyers prioritize design variety and brand compatibility. High-quality blocks come in a wide range of colors, shapes, and sizes, allowing for diverse creative possibilities. Additionally, compatibility with well-known brands, such as LEGO®, can be a valuable feature, enhancing the appeal of your product line. However, it's essential to respect intellectual property laws and ensure that any compatible products are marketed accurately.

7. The Hidden Costs of Opting for the Cheapest Option

Choosing low-cost building blocks might seem financially beneficial initially, but it often leads to higher long-term expenses. Consider the hidden costs that can arise:

- Higher Return Rates: Poor-quality blocks may result in increased returns and complaints from customers. Handling returns can increase your operational costs and impact your reputation.

- Lower Customer Satisfaction: If your building blocks lack quality, customers may avoid repeat purchases. Low-quality toys lead to negative reviews, which can harm your brand in the long run.

- Risk of Recalls: Products that fail safety standards or contain toxic materials are at risk of being recalled, which can incur significant costs and reputational damage.

8. Finding the Right Supplier: Key Questions to Ask

To ensure you're partnering with a reliable building block supplier, ask these questions:

- What materials are used in production? Look for ABS plastic or equivalent high-quality materials.

- Do you have certifications to verify product safety? Request documentation for certifications like EN71, ASTM F963, and ISO 9001.

- Can you provide samples? Sample inspection is essential for evaluating material quality, fit, and safety.

- What quality control measures are in place? Reliable suppliers often have comprehensive QC processes, inspecting products at multiple stages.

9. Conducting Quality Checks: What to Inspect in Samples

When you receive samples, conduct a thorough inspection for the following qualities:

- Material Quality: Check for durability and ensure there's no strong chemical odor, which may indicate low-quality plastic.

- Color Consistency: High-quality blocks have consistent coloring across all pieces.

- Structural Integrity: Attempt to assemble structures with the blocks to test the fit and stability.

- Surface and Edge Smoothness: Run your fingers along the edges to ensure there are no sharp parts that could be hazardous.

10. Sustainable and Ethical Sourcing: A Growing Priority

Sustainability is becoming an increasingly important factor in sourcing. Many manufacturers now offer building blocks made from eco-friendly or recycled materials, which can appeal to environmentally conscious buyers. Additionally, working with suppliers that adhere to ethical labor practices is essential.

Why Zhorya is a Trusted Source for Quality Building Blocks

Zhorya works with an extensive network of certified manufacturers to offer high-quality building blocks that meet stringent safety and quality standards. Our building blocks, made with premium materials like ABS plastic, ensure a reliable, safe, and enjoyable experience for children. With a commitment to rigorous quality control, ethical production practices, and sustainable options, Zhorya provides buyers with a trusted sourcing partner.

For more details, explore our building blocks collection and discover how we can support your business with top-quality building block products tailored to market needs.

Русский язык

Русский язык 中文

中文